OUR PRODUCTS

We took our step into Green Energy

Green energy :

The manufacture of yarn is an intensive energy consuming process. The Power shortage happenings should not be an impediment for the industry to function. Each and every industry needs to take part and play its role as a Corporate Social Responsibility by contributing its might to green energy production and enabling nature to replenish. With this in mind, the company ventured into the world of eco-friendly power generation using non-conventional sources of energy – the might of WIND.

Narasu’s installed Wind Turbine Generators with a capacity of 6.6 MW in Tamil Nadu, generate eco-friendly electric power and are fully automated, maintenance-free and environmentally friendly. The sole purpose of these WTG was to empower the state electrical board MW with additional power.

Energy-saving exercises are carried out to save power in the manufacturing processes. Minimising downtime is part of the energy-saving activity. Energy audits are conducted and regularly monitored as an ongoing process to reduce the leakage of power. Our company’s green policy to reduce electrical consumption every year is monitored effectively.

ABOUT NARASU’S SPINNING MILLS

Years of Operation

Our team have been running well for about 10 years and keeps going.

Positive Feedback

Based on our happy clients about the quality of our products & services.

Projects Completed

All projects competeled with an absolutely high quality

OUR PRESTIGIOUS CLIENTS:

DIRECT EXPORTS: We export to countries like PAKISTAN, AUSTRALIA, CANADA, MEXICO, UK, SPAIN, BAHRAIN, MALAYSIA, HONG-KONG, ISRAEL, TURKEY, UAE ETC.,

We are also equally strong with the local fabric exporters of Tiruchengode, Erode and Tirupur areas, and have also expanded to Guntur, Ichalkaranji, and Bhiwandi as benchmark quality suppliers.

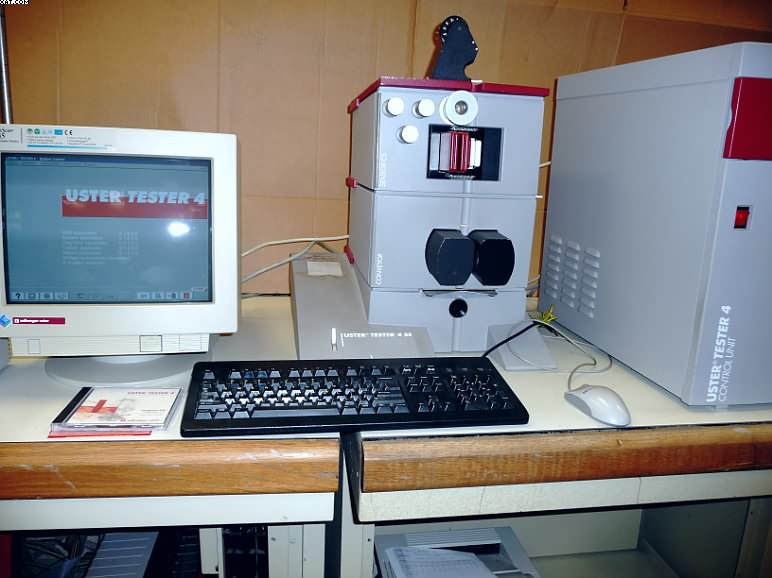

QUALITY CONTROL

1

UT 4 SE

2

CASCADE YARN TESTER

3

AFIS

We achieved a reputation for our quality, well within the international Uster Standards by having our better quality mechanism. A team of good technicians with a well-equipped Lab supports our good quality standards.

We are having the following testing facilities in our lab.

- UT 4 SE

- Cascade Yarn Tester

- AFIS

FINISHED PRODUCT & MARKETING:

Our finished product, a count range of 40/1s to 61/1s count cotton yarn, in both combed weaving and combed compact quality, meets the internationally acclaimed Uster 5 level and is very popular in both domestic and export markets. We have a good reputation in the market, resulting in receiving orders for export and from prestigious export houses and renowned EOU units.

We’d love to hear from you.

We are here to answer any question you may have.